Client: Ottobock

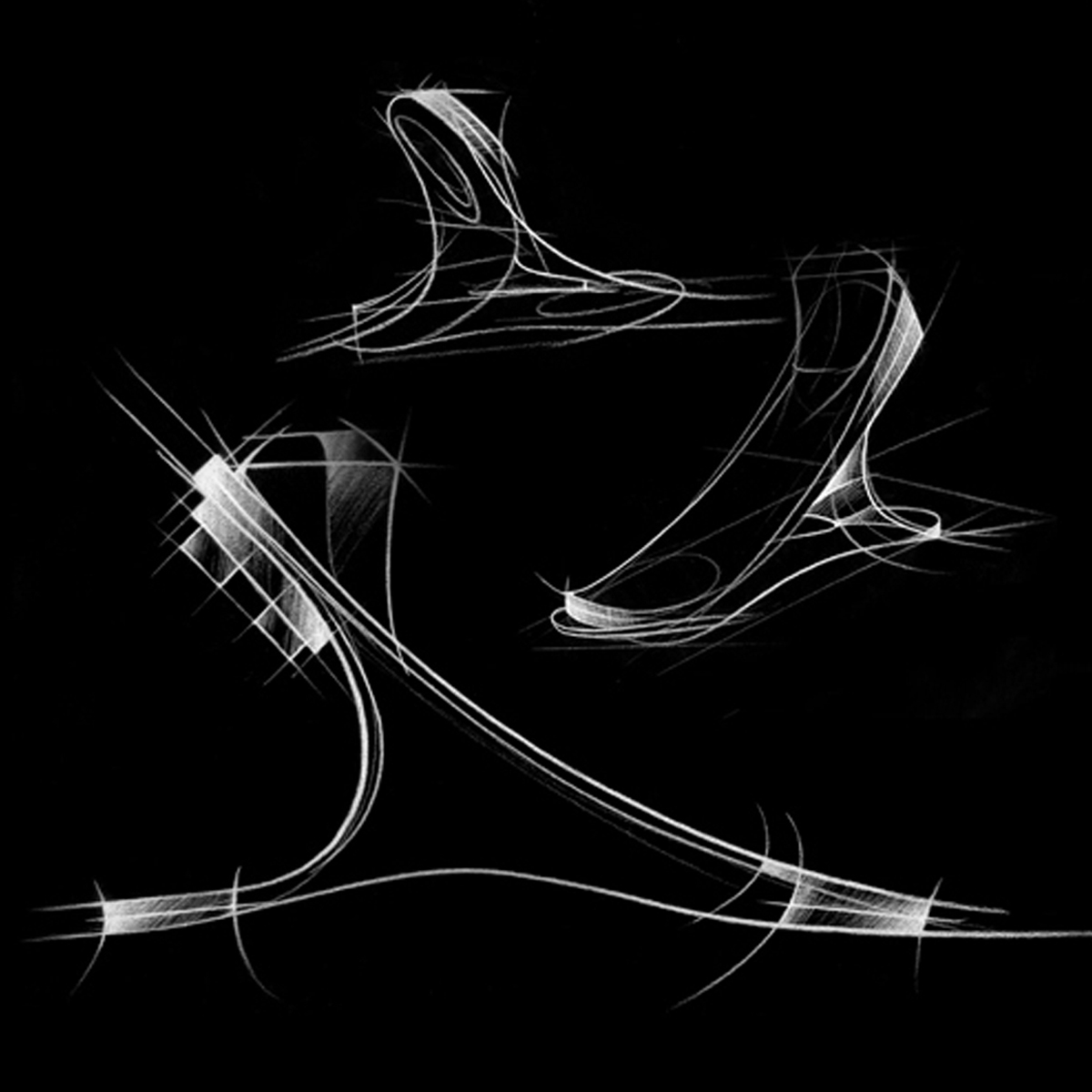

Ottobock approached us with the idea for a new prosthesis. One that would surpass the current performance offerings on the market for athletes. After gaining an understanding of the competition, Ottobock’s goals and customer’s use-case, we started by looking at the shape of a human foot.

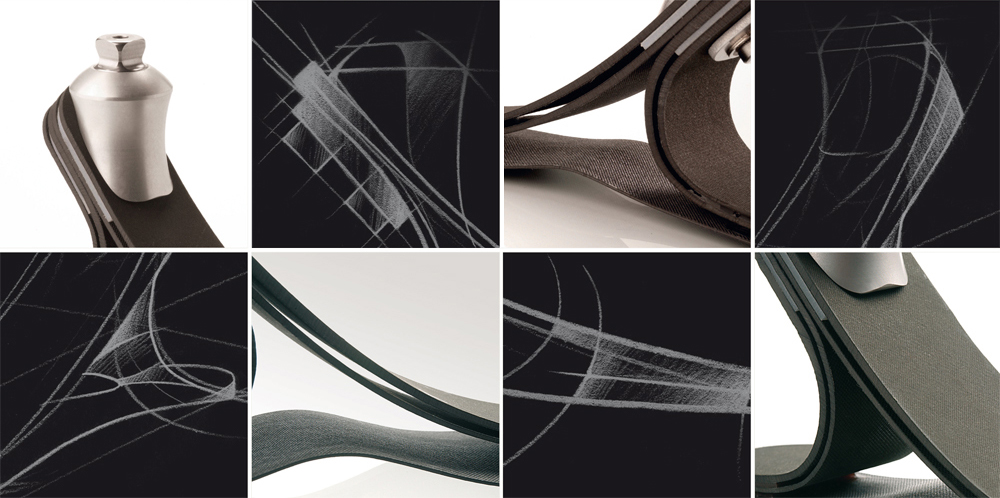

Anatomically, the curve of the foot’s arch allows for shock absorption and storage of energy for use in springing in to the next step. When we translated this shape to carbon, we were able to finely tune the mechanics of that energy transfer. With the arch profile as our starting point, we continued the idea of flexion by converting the naturally static human heel to a leaf spring. This allowed for massive amounts of travel, making heel strikes a non-issue to the user.

With much of the vertical forces taken care of, we needed to ensure that the foot was able to compensate for the types of side-load that are seen in sports such as Tennis or Skiing. Using urethane as the binding element between the carbon fiber components enabled just that. the Trias prosthetic foot was able to deliver the right amount of torsion and a rounding out of the shock absorption for optimal performance in any environment.

• Research

• Industrial Design

• Engineering

• Red Dot Design Award Best of the Best

• Legacy for the Future Award

• DesignArts Utah Jurors Award